The Liuxihe Hydropower Station is located in

the vicinity of Conghua City, 90 km away from Guangzhou City in Guangdong Province. The

dam site is seated on the gorge 1.3 km downstream of Xiaochuan village in Huangzhulang

township. It is mainly for power generation and

concurrently for flood control, irrigation, etc., which is a multi-purpose, comprehensive

utilization median-sized hydro-project.

The Liuxihe river basin is situated on north eastern to Guangzhou City,

standing between Beijiang River and Dongjiang River, the topography of which is

long-shaped in southern north and shallow-shaped in eastern west. Above the dam site,

there is mountainous hilly region with precipitous topography. The Liuxihe is of the water

system in delta estuary area, a tributary of the Pearl River Basin, having a total length

of 157 km and a catchment area of 2296 km2. In the river basin, 37 km above the

dam site, the controlled catchment area is 539 km2, sharing 23.5 % of the

total.

The said river basin is situated on the Tropic of Cancer, featuring

subtropical zone climate. The average annual design runoff is 1856 mm, the measured

average annual runoff being 2078.5 mm. The design average annual oncoming discharge into

the reservoir is 21.4 m3/s, whereas the measured value of which is 21.8 m3

/s after being put into commissioning. The design average annual volume of oncoming water

is 675 million m3, whereas the measured value of which is 688 million m3.

The total reservoir capacity is 375.8 million m3, the corresponding reservoir

capacity at normal pool level being 325 million m3, while the dead reservoir

capacity being 325 million m3, the benefit creation reservoir capacity being

239 million m3. The coefficient of reservoir capacity is 0.354, which is of an

incomplete reservoir for over-year storage.

The Liuxihe hydropower Station is a composite hydropower station, being

composed of a concrete arch dam, a subsidiary earth dam, a water diversion and surge tank

system, an underground power house and a flood discharge system, etc., being altogether 5

parts.

The project was begun constructing on August 1956. The reservoir

impounding was commenced on 20th June 1958. The No.1 power set was put into commissioning

and linked to the power grid on 15th August 1958 and the No.2, 3, 4 power sets were put

into operation on 17th September, 29th November and 23rd December of the same year in

succession respectively.

The project was designed in accordance with 100-year flood, the design

food level being 238.5 m (now adopting 237.60 m as approved by the former Ministry of

Water Conservancy and Electric Power Industry), the check flood level was designed

according to 1000-year flood ( now adopting 238.45 m as approved by the said ministry).

The normal high water level is 235.0 m, whereas the drawdown water level of the design

year is 226.0 m, the dead water level being 213.0 m and the limited water level for power

generation being 211.0 m.

II. Characteristic Indexes of the Main Hydraulic Structures

1.Dam

The main dam of the Liuxihe Reservoir is a concrete,

double-curvature, single arch dam. The elevation of the dam crest is 240.0 m, the width of

the crest being 2.0 m, the maximum bottom width of the dam being 22 m, the arc length of

the dam crest being 255.5 m, the maximum dam height being 78 m. The total volume of

concrete placement of the arch dam is 130,000 m3. The foundation grouting is

4,560 m, the gallery grouting being 2600 m, the structural joint grouting being 9,060 m.

The excavation of rock and earth work for arch dam foundation was begun from September

1956 to April 1957, totaling 65,880 m3. The concrete placement was started from

April 1857 and completed on September 1958. The condition of engineering geology in dam

site area is good with deep layer of granite, which is of densely crystalline sound and

hard rock. It is of Jurassic and Cretaceous period in geology.

The earth dam of the project is a subsidiary dam, blocking up the

low-lying land around the peripheral edge of the reservoir area. After the completion of

Huanglongdai Reservoir on June 1975, the other side of the earth dam is Huanglongdai

reservoir, which became to retain water at both sides. The dam is a homogenous earth dam

with a dam crest elevation of 241.7 m, a dam length of 220 m, a dam crest width of 4 m and

a dam bottom width of 210 m. In original design, the maximum dam height is 28.5 m. After

being checked by PMF standard, the dam is required to be upgraded, the maximum height of

which was revised to be 29.7 m. The earth-fill work of the earth dam is 350,000 m3.

2. Flood discharge structures

The flood discharge system has adopted a combined form of free surface

spillway on arch crest and associated with flood discharge tunnel.There are 7 free surface

spillways being provided at the arch dam crest, with a width of 11.5 m, a height of 4.0 m

for each bay opening. The elevation of the crest weir is 235.0 m. The maximum discharge of

each opening is 141 m3/s. The operation mode is of free surface spilling flow.

A sky jump energy dissipater with differential high and lower sill is adopted. The flood

discharge tunnel,built on the right-bank, embraces a total length of 237 m, which is a

free surface flow tunnel. One set of steel plain gate is equipped to control the flow. The

elevation of entrance bottom sill is 224.9 m, The cross section of the tunnel is of a

horse-shoe type, 7.2 m wide, 8.9 m high, being capable to have a maximum design discharge

of 1070 m3/s.

3. Water diversion structures

The power tunnel is provided at the right bank, embracing a total

length of 1928.07 m, with a circular cross section. A part of the tunnel has

concrete lining, with an inner diameter of 4.5 m, whereas the inner diameter of the

unlined part is 6 m. The top elevation of the morning-glory haped entrance is 217.10 m,

the bottom sill elevation being 206.5 m, the centerline elevation being 208.75 m. The mode

of water diversion is of pressurized flow diversion, the maximum discharge available being

51.4 m3/s. At the end of the power tunnel, a differential surge shaft is

provided, after which a penstock is provided, having a length of 140.0 m and an inner

diameter of 4.5 m.

4. Power station

An underground powerhouse is adopted in the Liuxihe Hydropower Station.

The power house is located on the right bank downstream of the dam, in which 4 T-G sets

are installed. In original design, the installed capacity is 4 x 10.5 MW. Since 1993, the

power sets are enlarged and upgraded. After completion, the installed capacity is turned

to be 4 x 12.0 MW. The design average annual output is 154.6 million kWh, the firm output

being 138 million kWh ( P=90 %). In actual performance, the average annual output is 146.7

million kWh. The original Model of the hydro-turbine is HL38---LJ---140, while the Model

of the power generator is TS---286/135---12. At present, the Model of the hydro-turbine is

HLA553---LJ---140, while the Model of power generator is TS---260/135---12.

III. Color Photos

Photo 1.

Fragrant Creek Garden (Main entrance of the power plant)

|

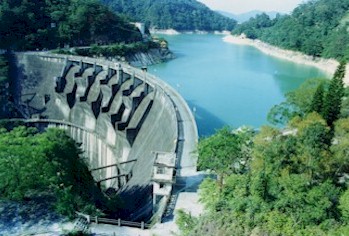

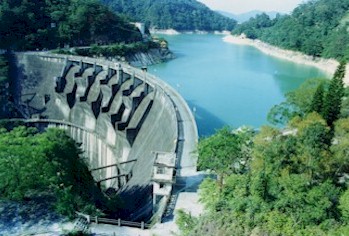

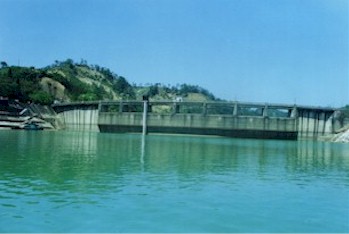

Photo 2.

A long rainbow sleeping on the crystal clear pool (Bird eye view of the arch dam)

|

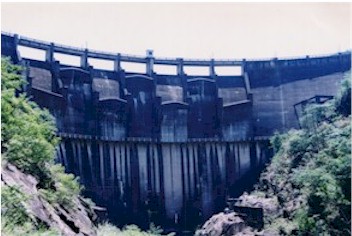

Photo 3.

An arch dam calming the stream (Upstream view of the

arch dam)

|

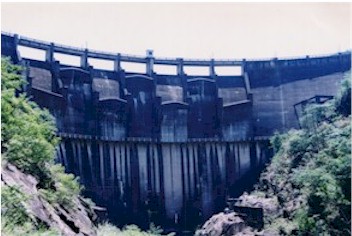

Photo 4 A

magnificent view of the arch dam (Looking up at the arch dam from downstream)

|

Photo 5 Underground power

house |

IV. Distinguishing features and characteristics in technological

aspects in the construction of Liuxihe Hydropower Station in Guangdong Province

The Liuxihe Hydropower Station has been one of the key engineering

constructions listed in the state-run first Five-Year plan. It has also been one of the

great practice of the State-run hydropower construction, following the building of

Fuziling, Guanting, Gutianxi first phase, first stage of cascade development, Shizitan,

Meishan and Shangyoujiang. It is the seventh median-sized hydropower station after

the founding of New China, being a multi-purpose project mainly for the exploitation of

water power resources. The river basin planning work was started on September 1955, while

the preliminary design was begun conducting on January 1956. The said project was begun

constructing on August 1956, the first power set was put into operation on August 1958 and

all four power sets were put into commissioning in the same year.

1. The characteristic features of the project

The river bed at the dam site of the Liuxihe Hydropower Station

appears in V-shape. All mountain slopes are steep and precipitous. The bed rock is of

granite with simple geological structure. The dam has adopted a variable radius and

variable central angle as well as variable thickness circular arc, concrete

double-curvature arch dam. The characteristic ratio of bottom width and dam height is B/H

= 0.283, being the first thin arch dam ever adopted in China during that time.

The overflow spillways are provided at the arch dam crest, which

is the first case of flood spilling at the arch dam crest. There are seven bays of

spillway, without the provision of gates at the dam crest, being of the free surface

spilling type. The sky jump energy dissipater with apron sills at high and low levels are

installed at the end of spillway, thus making the water flow mutually collided in open air

for energy dissipation. In later stage, for the sake of convenience in flood dispatching,

mitigating the erosion of dam foundation due to flood discharging from surface spillway, a

flood discharge tunnel was built on the right bank in addition to other discharge

facilities, thereby making possible to adopt a combined flood discharge scheme. The flood

discharge tunnel is mainly responsible for flood release associated with the flood

discharge function of the spillway on the arch dam crest.

In 1969, a flexible rubber dam was additionally built on the weir

crest of the spillway, acting as a controlling gate to retain flood, which could be used

for power generation during the tail period. Hence, it is possible to elevate the pool

level 2 m, thus increasing power generation benefit.. Owing to the instability of air

pressure within the collapsible rubber dam bag, causing surplus discharge and endangering

the downstream flood control safety, the flexible rubber dam was dismantled in 1987.

The reservoir was built without reserving a bottom outlet for reservoir

emptying.A water depth of 30 m still remained in front of the dam, the corresponding

reservoir capacity of roughly 45 million m3 failed to be emptied. Once the

safety problem of the arch dam encountered, it will be more difficult to strengthen the

project or to take any remedy measures.

2. Characteristic features of the project construction

The main engineering quantity of the Liuxihe Hydropower project

are: earth and rock excavation work 680,000 m3, earth-fill work 250,000 m3,

concrete placement 187,000 m3. As the hydro-project is located in the narrow

gorge, the general layout of the construction site is more difficult.

A semi-automatic concrete mixing plant is employed for dam

concrete. Light rail concrete transfer truck and 9-ton gantry crane., etc. are adopted for

mechanized construction. The effective period of construction for concrete placement

reached nearly 12 months. The average monthly volume of placement reached 11,000 m3,

the peak monthly placement being 20,600 m3. The coefficient of non-uniformity

is 1.8 --1.9. The fourth grading concrete is used for dam proper, the max. grain size of

aggregate being 150 mm. The #140 - #250 concrete are used for different parts of the dam

project. The design criterion of concrete is 120 day-strength, combined materials

additives, plasticizing agent, stone block buried are used in concrete mixing. Attention

is fully paid on lowering the placing temperature and heat dissipation. problems. During

early stage, design has been made to reserve heat dispersion shaft within the dam proper.

Such a scheme, after being carefully studied and compared, it has been revised to adopt

the method of adding cooling water and mixing acicular ice as well as burying cooling

water pipes within the dam proper, thereby conducting new technique of I-phase and

II-phase cooling. It has yielded promising and successful results.

During the high peak period of construction for the Liuxihe Hydropower

Station, the total labor force reached 14,000 persons. There are nearly 5 million

labor-day to complete the said hydropower station. All items of temporary structures are

nearly 100,000 m3. During peak period, the monthly power consumption for

construction reached 1.30 million kW.h.

3. Fast in construction speed

The general progress of construction for Liuxihe Hydropower

Station is: the planning work of Liuxihe River Basin was started on September1955. The

preliminary design was completed on June 1956, altogether lasting 9 months. The project

was formally started constructing on August 1956 and the first power set was put into

operation on August 1958, the construction of which lasted 2 years. The station was wholly

completed on January 1959, the total construction period was less than 2 years. As a

whole, the Liuxihe Hydropower Station, starting from the commencement of river basin

planning up to fully completion, altogether lasted less than three and half years. The

construction speed is comparatively fast.

4. Low in engineering cost

On the aspect of dam site selection, the Liuxihe Hydropower

Station has screened five dam sites. In accordance with the concrete topography,

geological condition, interfaced with the comparison of various dam types, finally the

fourth dam site was selected, where dam site rocks are relatively sound, with thinner

layer of weathering and lower in investment. In dam type selection, five alternative

schemes have been compared, in which the arch dam is the most preferable for its least

investment, being equivalent to 2/3 that of gravity dam or rock-fill dam. In the aspect of

engineering quantity, the amount of excavation and residue cleaning as well as the

concrete of the dam proper is relatively less in amount. In the design of arch dam, the

dam crest spillway scheme has been adopted, which is simpler in layout and economical in

engineering cost as compared with river bank spillway and water release outlet within dam

proper. Based on the geological condition, a length of 800 m of the power tunnel could

merely use shotcrete in stead of concrete lining, thereby reducing the engineering

quantity and saving investment. In the layout of power house, the main power house is

arranged in line with the subsidiary power house and the central control room is situated

on one terminal of the main power house, thus forming a compact arrangement and

consequently reducing the engineering quantity. Owing to the fact that optimization has

been carried out in the design and the optimal scheme has been selected and the new

structure and new technology have been adopted, thus making the investment of cost

estimate per unit kW reduced to 1100 yuan (rmb).

The cost saving measures were employed during construction, such

as: in the aspect of technologies, as regard to the livelihood during construction, the

bamboo structures were adopted for office building and the bamboo reinforced concrete

structures were used for the partition wall of warehouse for materials. The upstream

cofferdam designed is of rock-fill bodies overflow type. In order to save cement, the

coarse aggregates with the max. grain size of 150 mm were adopted in dam concrete.

Furthermore, 5 % - 10 % of white soil or 1 % platicizer, 7 % buried stone block were used

as additives or coarse aggregate. To utilize later age strength after 120-day as design

criteria and to use different grade concrete at different places, etc. are all effective

measures to save cement. In the aspect of management, to implement budget of construction

drawings, engineering task list, limited amount material list, etc. to reinforce cost

management in an overall point of view, to pay serious attention to cost analysis, to

combat waste and to establish award for reasonable suggestions, award for saving in

engineering issues.

As grave attention has been paid on the saving measures both in

technology and management during construction, the actual engineering cost is

40.54 million yuan, being reduced 13.7 % of the total cost estimated., the cost per unit

kW being 965 yuan (rmb). The cost was relatively low for a median-sized hydropower station

during that time. After 40 years operation, it has witnessed that the saving measures

taken in construction did not influence the engineering quality, which was esteemed

to be good and promising.

5.Excellent in quality

The attention has been strongly focused on the engineering quality

by the construction unit of the Liuxihe Hydropower Station. Various measures have been

taken, to observe strictly the quality control procedure. In order to well construct the

arch dam, a strict and reasonable organizational design of construction has been made.

More strict requirement has been proposed for the excavation treatment for the dam

foundation, the in-situ inspection and acceptance as well as the quality control of

concrete. With an aim at controlling the precise dimensions of the dam block of a

double-curvature arch dam in concrete placement, specific persons have been appointed by

the engineering bureau to compute every layer and every block in advance. In order to

guarantee the quality of construction, the experiment personnel have been specifically

trained. Experiment laboratory has been established. With an aim at controlling the

temperature of concrete, the pre-cooling of concrete and cooling water pipes have been

buried within the dam. Simultaneously, systems of quality monitoring and accident

treatment, etc. have been established together with strict implementation.

All measures implemented during construction have ensured the

quality of construction for the project. No crack has been found in the dam proper. The

quality of grouting for transverse joints is excellent. The deformation of arch dam is

quite small after reservoir impounding. No leakage in the concrete dam proper has been

found. The vibration of dam proper during flood discharging is slight. The power tunnel

after being put into operation, despite a part of the tunnel has not been lined with

concrete, however, the surrounding rocks remain stable.

The Liuxihe Hydropower Station has been put into operation for

more than 40 years. However, up to the present moment, all items of the main structures

have had smooth functioning, enjoying good praise from various aspects.

6.Briefing on the operation situation of the arch dam

Owing to the fact that the Liuxihe Hydropower Station is

reasonable in design and strict in construction, therefore, the quality of the

project is excellent. During the past 40 odd years, the project is in smooth

operation and normal management. The first periodic inspection on dam safety was

carried out in 1989. The appraisal made by the specialist panel witnessed the fact

the Liuxihe arch dam has been esteemed as C-class (normal) dam. In 1997, the project has

been registered by the dam safety supervisory center as an A-class dam. The second

periodic inspection on dam safety has been started from 1999 and will be completed in the

first half year of 2000.

The present items and apparatus for safety monitoring in Liuxihe

Hydropower Station are: 1. horizontal displacement, new and old video level line

system, arch crown inverted plumbing line, dam shoulder inverted plumbing line, geodetic

quadrangle plan control net; 2. vertical displacement; 3. variation of structural

joints;crack observation on downstream dam surface.

The displacement on Liuxihe arch dam has regular variation on one

side, and the non-reversible displacement toward upstream is in existence, which tends to

be essentially stable at present. After being operated for 40 odd years, the concrete of

arch dam proper has had nice outer appearance. Generally speaking, the overall situation

is relatively good. The weathering and erosion phenomena on both upstream and downstream

concrete dam surfaces are not serious. Only an extremely small part has naked its coarse

aggregates, while most part of the concrete surface are smooth and flush. However, cracks

were found on the dam surface during the early stage and operation period, among which the

cracks occurred on the downstream surface were more numerous. Practically, no leakage was

found either on dam proper or on dam foundation. Besides, the property of cracks is

pending further investigation to be clarified. The remaining situations could witness that

the structural behavior of the dam is excellent and promising.

7. Precious experience

The completion of Liuxihe Hydropower Station is an important

starting point.It is not only served as a creative work for the development of electric

power industry in Guangdong Province, it has also accumulated precious experience of

hydropower construction. Furthermore, it has trained a lot of personnel and technical

mainstay as well. Since 40 odd years?operation and commissioning of the station, it has

provided low-price power for industrial and agricultural production of the Guangdong

Province. It has played evident role for flood control, irrigation and domestic use for

the local people. The Liuxihe Hydropower Station is the first hydropower station in

Guangdong Province since the founding of New China. It has shouldered the responsibility

of training task, training the operation personnel at various levels for other provinces

and districts and providing a good base for practice, as well as playing an important role

for the development of hydropower undertakings.